Hardened electroless nickel plating

Wear-resistant

corrosion protection!

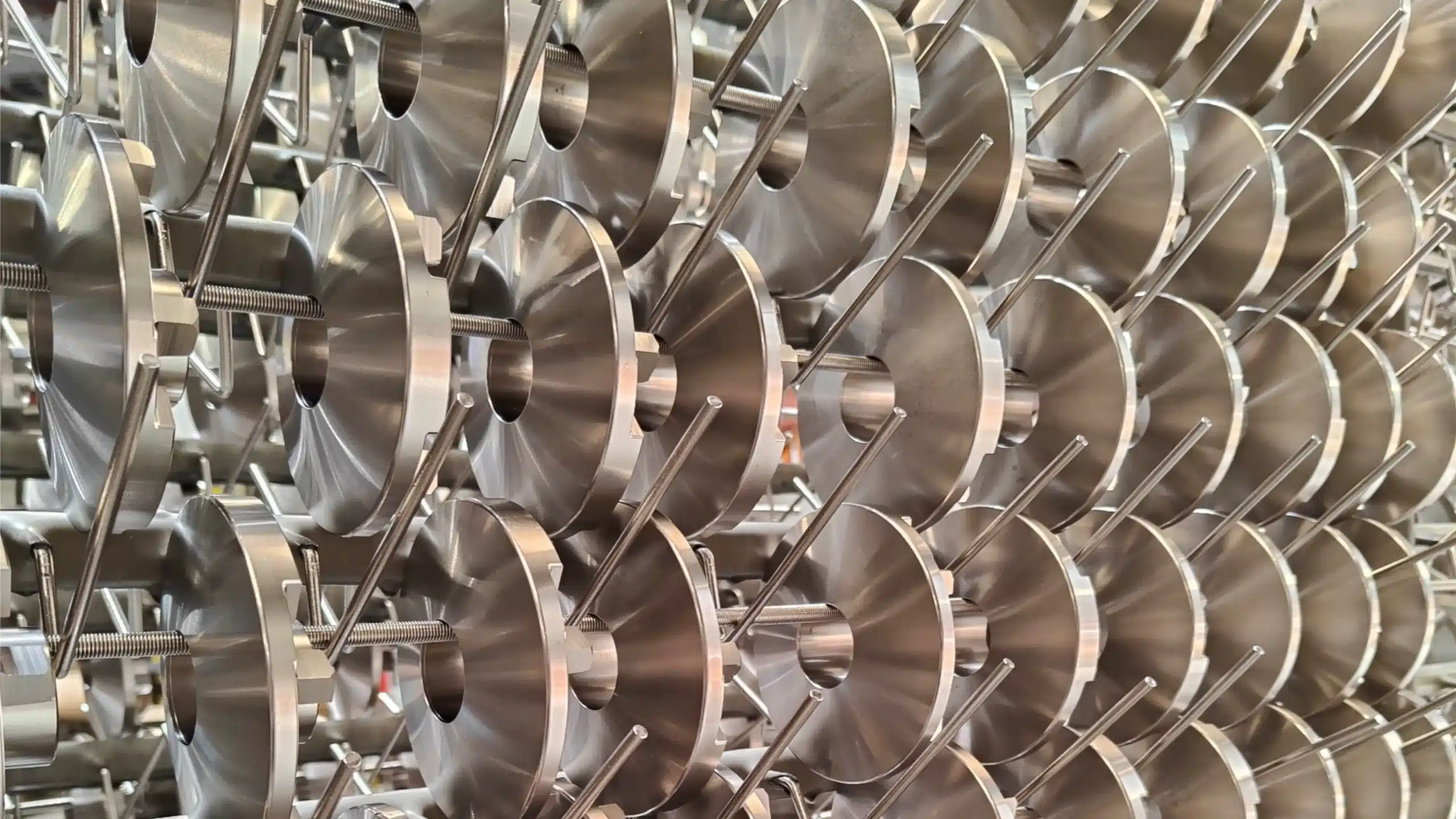

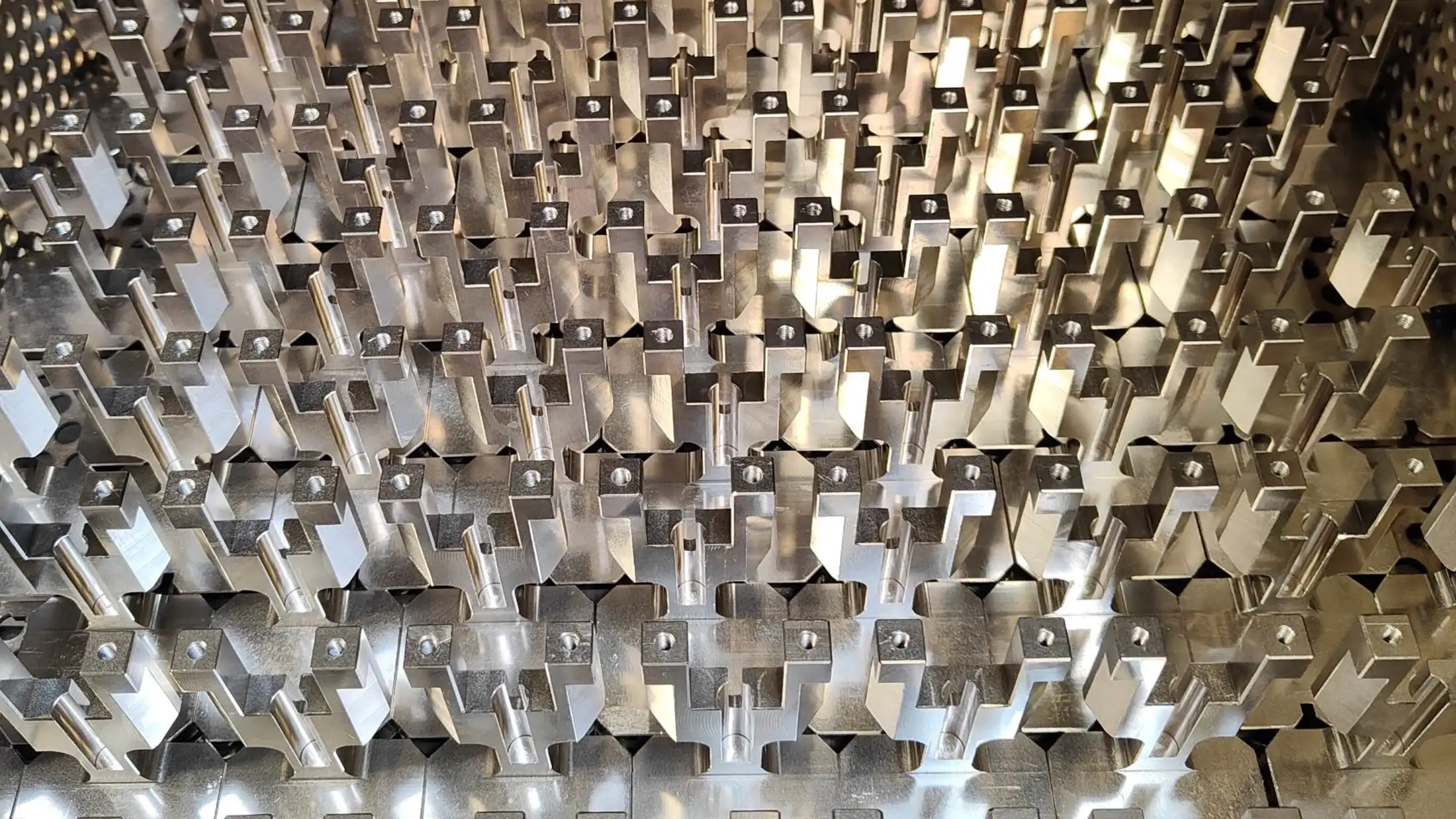

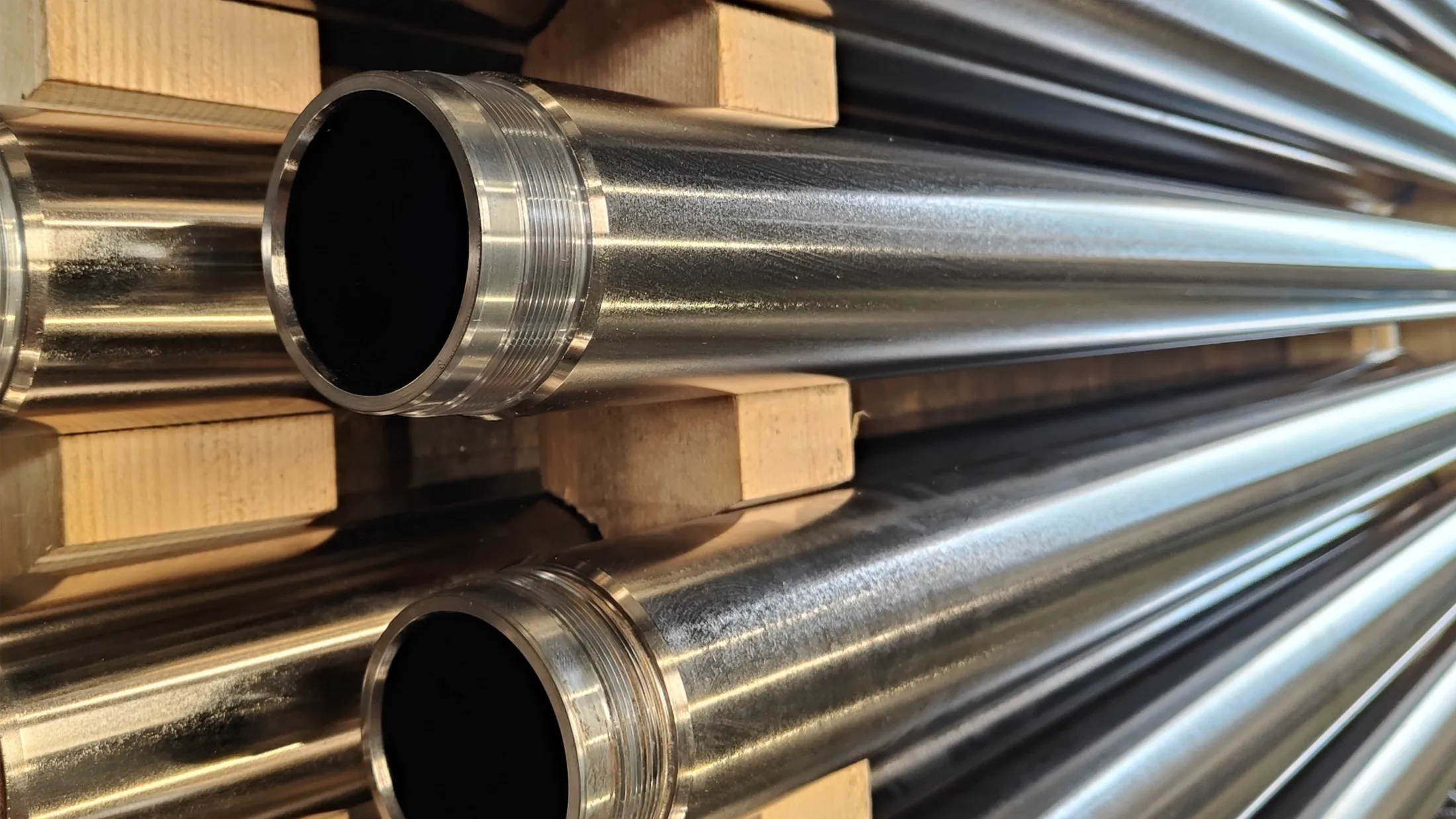

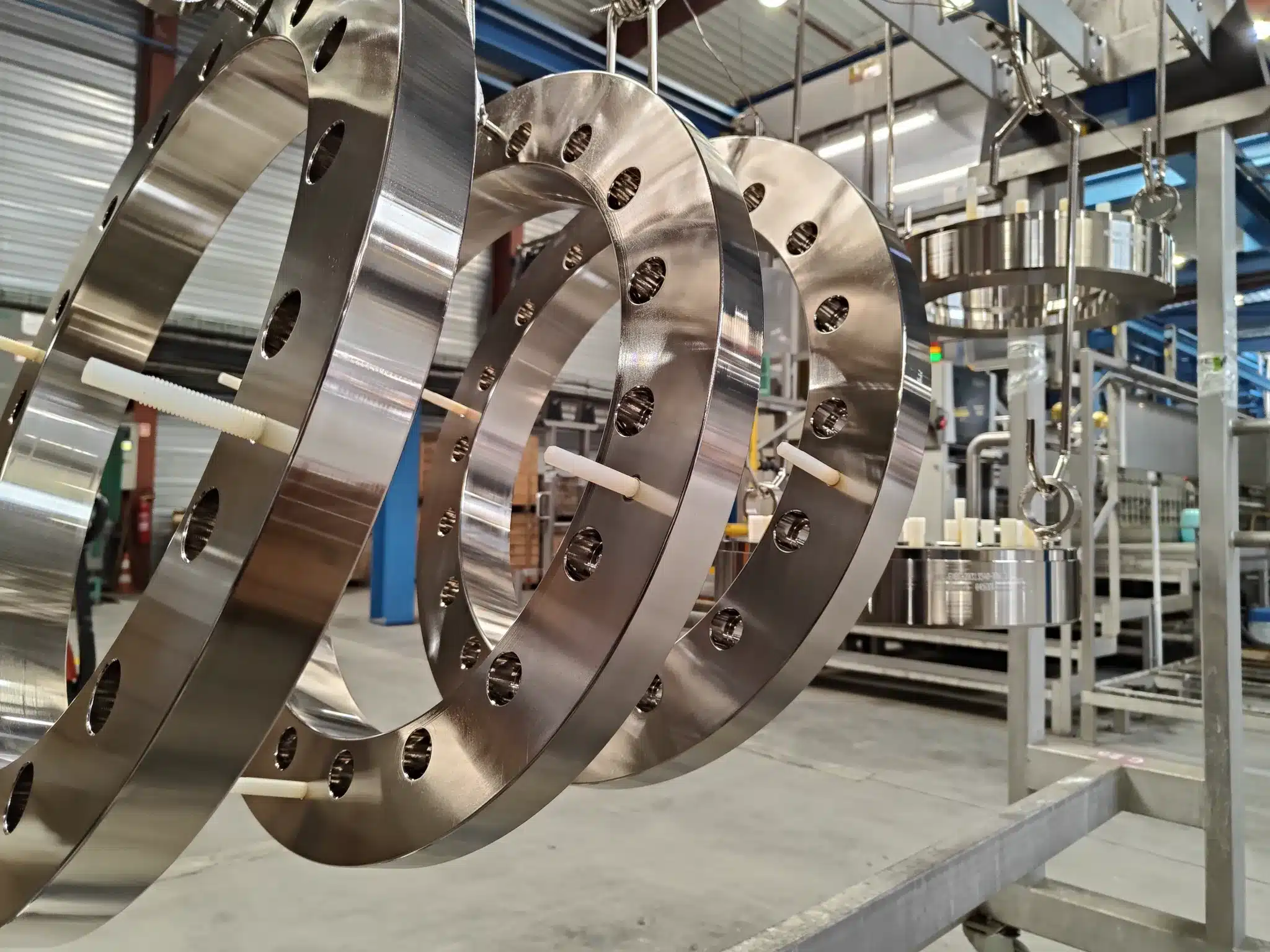

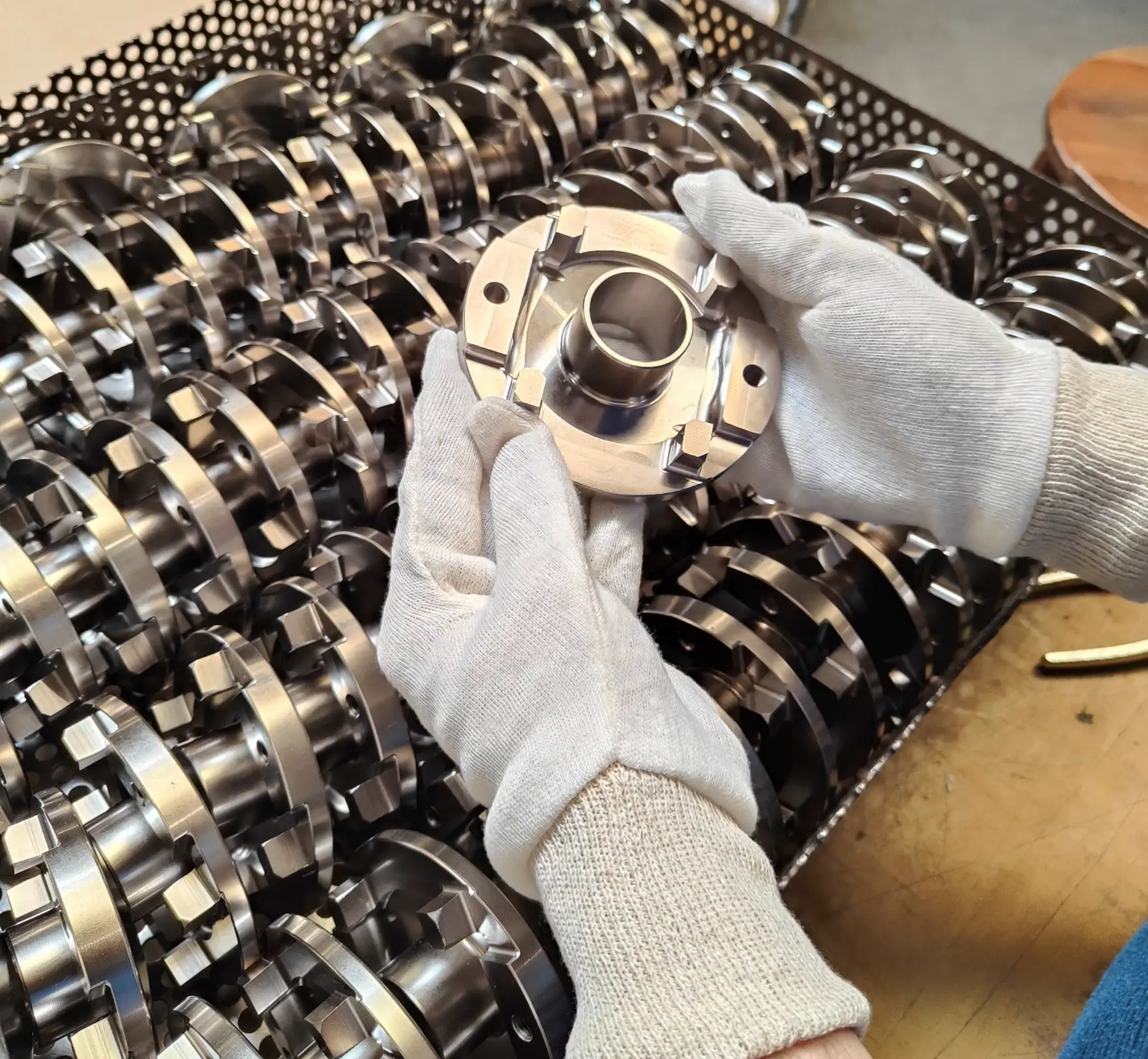

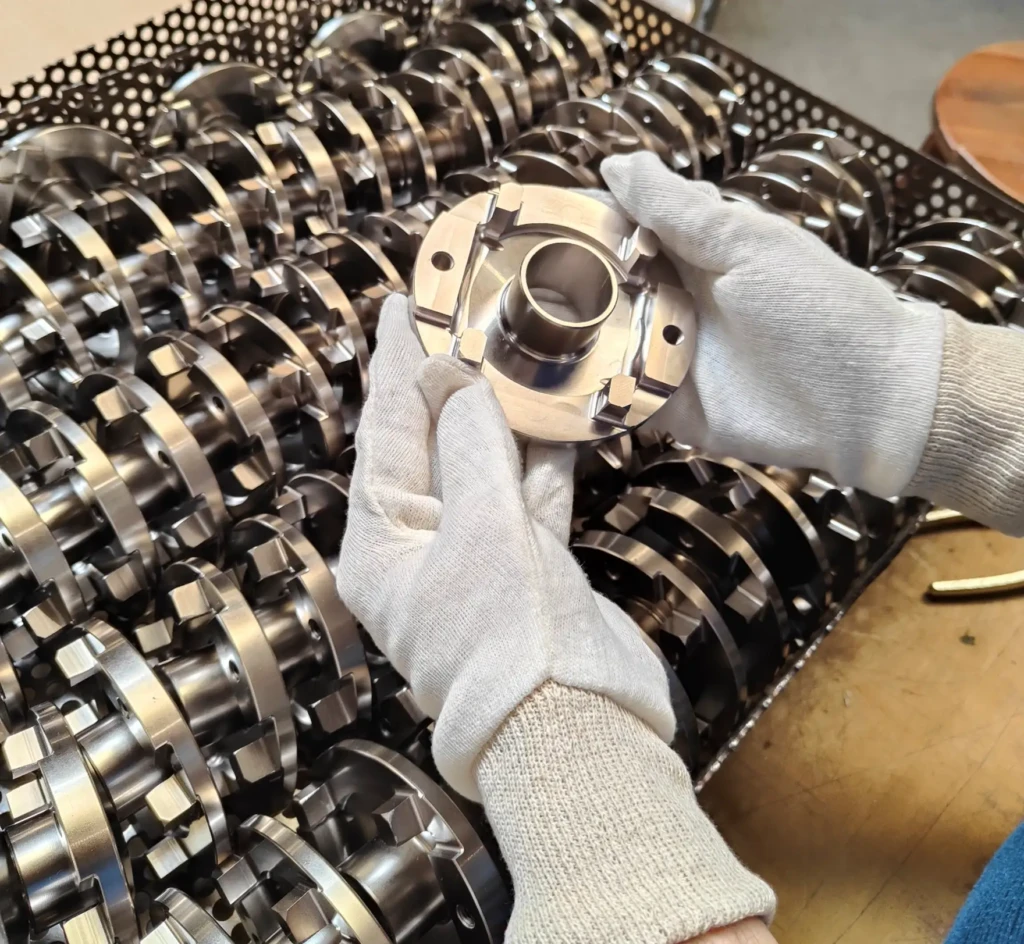

Made from high phosphorus electroless nickel for enhanced performance, hardened electroless nickel plating offers exceptional hardness, making it the ideal choice for “tough” mechanical applications.

Exceptional Hardness

Following a carefully calibrated heat treatment at temperatures of 300 or 400°C depending on the material, hardened electroless nickel plating can reach a minimum hardness of 850 Vickers (Hv0.1) while maintaining high-performance corrosion protection.

Suitable for all types of wear

Whether your parts are exposed to wear from friction, abrasion, erosion, cavitation, etc. they will have the excellent protection of hardened electroless nickel plating. This treatment enhances part surface hardness, minimises wear and significantly increases service life.

Increase performance

As well as increasing wear and corrosion resistance, hardened electroless nickel plating optimises friction and improves the performance of your parts in the most demanding mechanical applications. You can use it to make your systems more reliable and reduce breakdowns, maintenance and downtime.