Electroless nickel plating in detail

Electroless Nickel plating

in detail

Discover the different specificities of nickel plating: its deposition principle, the different heat treatments, savings (or masking) and our tools.

The nickel deposition principle

The electroless nickel deposition technique on metal substrates is widely used in various industrial sectors. Deposition processes are complex and depend on a number of parameters such as pH, temperature, the composition of the electroless nickel treatment baths and the nature of the substrate, all intended to create the best electroless nickel deposition conditions.

The electroless deposition process begins by immersing the parts in surface preparation baths, in particular to degrease and pickle them, which guarantees the molecular adherence of the electroless nickel to materials such as steel, aluminium, copper, cast iron or alloys.

The parts are then immersed in a solution containing nickel salts (sulphate), reducing agents (hypophosphite) and additives (acids, complexing agents, surfactants, etc.).

That triggers an autocatalytic reaction:

NiSO4 + 3 NaH2PO2 + 3H2O → Ni°(P) + 3 Na+ + 3H2PO3– + SO42- + 2 H2 + 2 H+

In other terms:

Nickel sulphate + sodium hypophosphite + water → nickel-phosphorus alloy

The different types of treatment

- “As-plated” treatment provides simple, long-lasting corrosion protection, ideal for the long-term protection of your parts. It is recommended for applications not subject to severe mechanical stress.

- Degassing heat treatment gives the electroless nickel deposit better adherence and greater strength by eliminating the hydrogen included in the layer.

- ”Hardened” nickel, obtained after heat treatment at between 3 and 400°C, significantly increases the hardness of high phosphorus content electroless nickel plating while maintaining satisfactory corrosion protection. It is especially suitable for parts subject to frictional wear, extending their service life in demanding mechanical applications.

- Diffusion heat treatment provides exceptional corrosion protection while improving hardness compared to the “as-plated” treatment. It confers excellent resistance to saline mist and a perfect bond between the electroless nickel layer and the substrate. It is especially well adapted to severe mechanical applications in aggressive corrosive environments.

These different electroless nickel plating methods are used to optimise the durability and performance of your parts according to your specific requirements.

Masking: partial protection from nickel

Masking is a technique that is used to partially protect parts from electroless nickel plating when absolutely necessary. This method can sometimes be complex to implement and goes against the nickel plating philosophy, which is generally intended to completely cover the part with a metallic layer to provide total sealing. The masked area can be the potential starting point for corrosion.

However, this process offers the possibility of not coating a specific area of your part when its characteristics (dimensions, materials, etc.) make this absolutely necessary.

We can apply masking to steel, aluminium, copper, cast iron and their alloys to meet your specific needs.

Optimise your electroless nickel plating process using our range of tools

At Verbrugge, quality is the most important aspect of our production. Which is why we have a wide range of innovating tools available to meet all your needs.

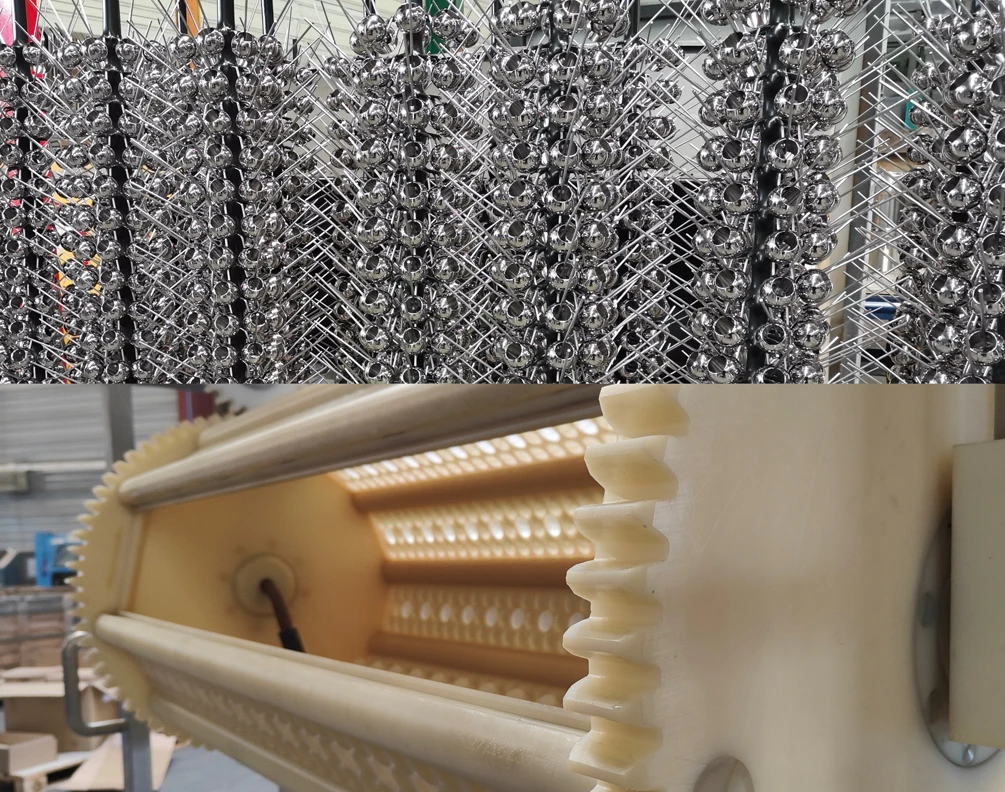

- Christmas tree: Our different Christmas tree assemblies are a reliable and versatile solution for hanging your parts during electroless nickel plating. They offer secure fixing.

- Barrel: Our barrel system is designed to process batches of parts that do not allow contact points. This cost-effective process guarantees consistent electroless nickel plating providing constant quality.

- Pendulum assembly: The pendulum assembly is an effective alternative if your parts are fragile and complex. It is designed to control rotation and minimise impact between parts.

- Rotating assembly: For the most complex shapes, or even without contact points, our rotating assemblies are the ideal solution. They provide full rotation to ensure consistent coating in even the most inaccessible recesses.

- Basket: Our baskets are designed for parts that can simply be placed on a surface. It is a practical solution for treating parts of different shapes and sizes, guaranteeing the efficient use of treatment space.